Our engineers are present at every stage of the product creation process, from the concept to serial production. We execute orders both internally and externally at the customer’s premises through our employees.

We offer mechanical engineering and automation services (cad/cam design, machining, production tooling, machine manufacturing) and supplier quality development services (to assist in solving quality problems or when resources are insufficient).

Experts in invenio have extensive experience in the design, operation, construction and manufacture of machinery and assembly stations, as well as in the development and manufacture of Instruments and handles necessary for a variety of production processes. With our support, companies manage their resources better, increasing efficiency and reducing the number of problems in the production process.

The company’s competence in CAD design includes areas such as the design of manufacturing instrumentation (control checks, manufacturing tools), workstations, and machines and devices.

Invenio also has experience in the design of research stations and specialized devices designed for the needs of research institutes and technical universities.

Our expertise and effectiveness of our solutions have been recognized by specialists. The load conical gears test station designed for the Institute of Technology and Machine Operation (the National Research Institute in Radom) was presented, among others, in Moscow in 2013, at the International Salon of Inventions and Innovation Technologies Archimedes, where it won the gold medal.

We use the software :

We guarantee a smooth design process and a high level of insight into the analyses developed.

Invenio supports its clients by posting design engineers to work at the client’s site. The scope of the work consists mainly of manufacturing instrumentation or product changes. Development work is also included, if necessary. The design engineer may be posted to work using Client’s hardware as well as with the CAD station and the type of software agreed with the Client. Using the individual findings, invenio selects an employee with qualifications appropriate for the project.

We offer comprehensive solutions for the automation and robotisation of production processes, which include the integration of several machines that are part of a process by means of feeders, conveyors, trolleys and AGVs. This makes it possible to replace human labour with robots wherever possible.

Automation involves the use of specialised software and devices that automatically carry out some or all of the production operations. This makes processes on the production floor more efficient and precise, leading to increased productivity and production quality.

Robotisation works on the basis of high-tech manipulators and associated equipment such as automatic feeders. Robots equipped with sensors and sensors are used, which enable precise operations and remote communication with the environment.

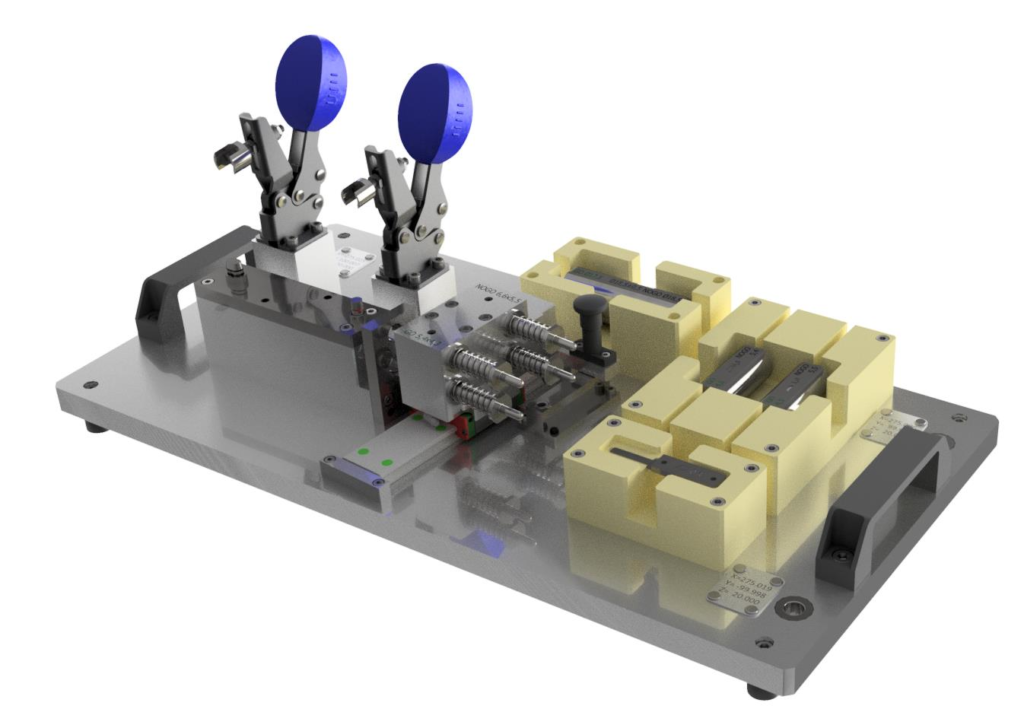

We have extensive experience in the design and manufacture of specialized manufacturing instrumentation. We provide our clients with dedicated solutions to specific problems by streamlining and optimizing their production processes.

In addition to purely engineering services, we also deal with the production of machines, devices, and manufacturing instrumentation based on our own tool plant. Support from invenio includes CAD design, manufacturing, assembly, and the implementation of our solutions at the client’s site.

One of the invenio’s specialties is the design and manufacture control checks. These are go / no-go type checks that allow you to quickly assess the geometric properties or the essential functions of the product.

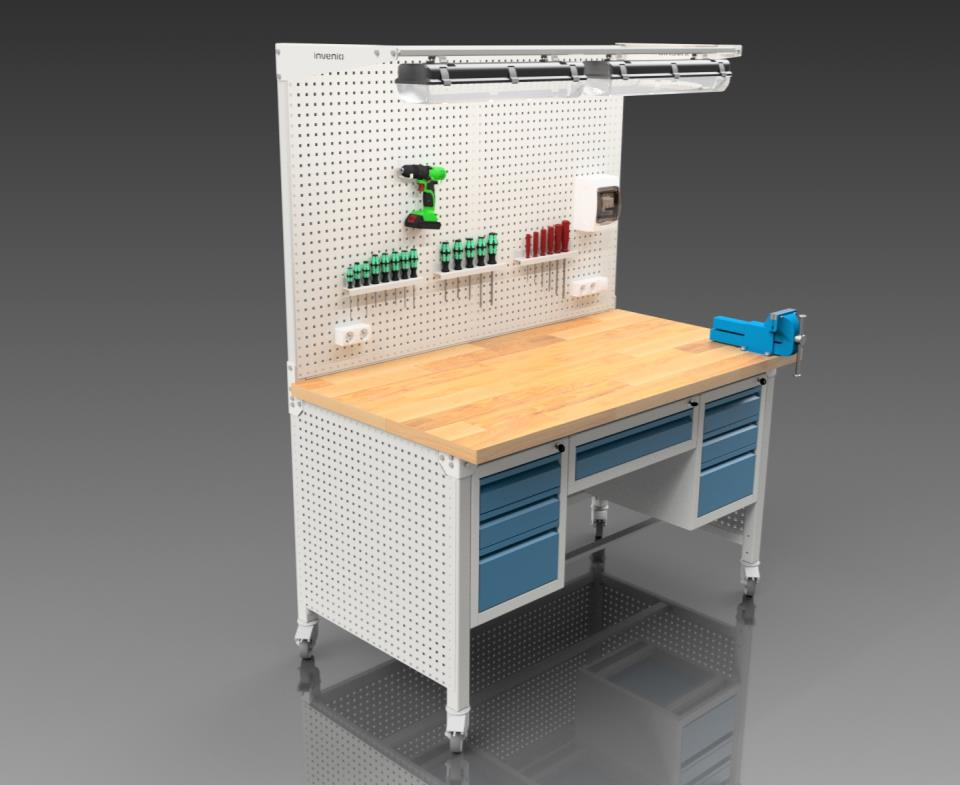

invenio develops assembly workstation designs for small and high volume production, particularly for the automotive industry. These are designed in accordance with ergonomic principles and Lean Manufacturing. For our customers, we also manufacture specialised workstations to meet individual requirements, as well as trolleys, pallet platforms and ancillary equipment for production.

As a market leader in quality control services, invenio has a state-of-the-art measurement laboratory. The services offered are dedicated to customers for whom the highest quality is the basis of their business, and they do not have their own measurement laboratory or suitable specialists. Measurements are made using the FARO EDGE 2.7m measuring arm with an accuracy of 0.041mm for a single point and inspection software.

We also manufacture machine tools, including specialised industrial tools, precision handles for holding components firmly in place during machining and gauges for quality control and dimensional conformity of products.

We offer workbenches as equipment for repair shops, mechanical workshops, tool shops and factories. Our workbenches are robust, functional and adapted to various production and repair needs, providing a comfortable and efficient workplace.

Conveyor systems are used for in-plant transport of materials, semi-finished goods, products, e.g. between process machines on a production line or for storage/packaging purposes. They have their own drive. The movement of goods on the conveyor takes place without human intervention. On the other hand, feeding onto and receiving can be carried out by a human, machine or robot.

Thanks to the use of modern machinery and a qualified team of specialists, we are able to put into production and execute all our projects in order to provide our customers with the highest quality complete solutions.

Our machine park is equipped with precision machine tools from FOP AVIA (lathes and vertical milling centres), which work together with high-end manufacturing support software.

Based on extensive engineering knowledge and industry experience, we perform the measurements needed to reproduce the missing 2D and 3D CAD technical documentation.

With our measurements, we create the 3D CAD environment needed for further design work, for example, for machine overhaul and upgrades.